2018’s Top 3 Trends in 3D Printing

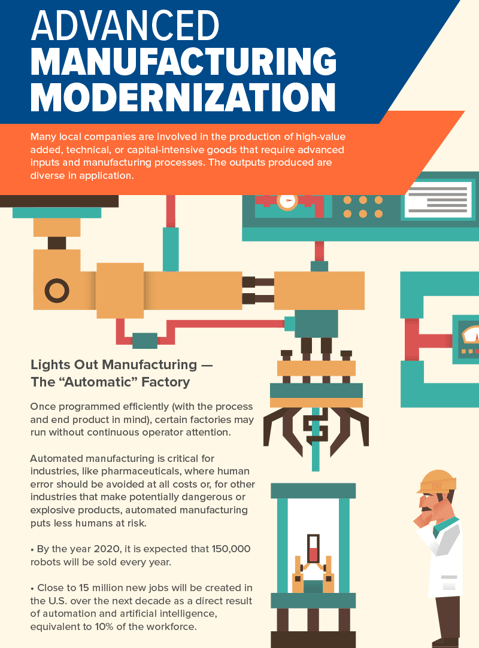

Just a few short years ago, the topic of 3D printing seemed confined to engineers and scientists. Today, it’s becoming a household term as one breakthrough after another makes headlines and brings the technology one step closer to widespread availability and new applications.

In the Santa Clarita Valley alone we have several 3D printing companies, like Stratasys Direct Manufacturing, which has conceptualized and produced parts for use across the aerospace and biomedical industries.

The technology, which has been available since the late 1980s, is rapidly evolving right alongside the industries it serves, with the potential to radically shift life as we know it over the next few decades.

Here are three emerging trends we are seeing this year:

- Innovative Applications Across Vertical Markets

From the start, 3D printing primarily used plastics due to their lower cost and pliability. Over the last year, however, we’ve seen the technology take great strides with new materials, like metals in both the automotive and aerospace industries. Earlier in 2018 we saw some success in the biomedical space when researchers from MIT successfully 3D printed genetically-programmed bacteria. Coupled with promising technological advancements towards printing viable organs, the healthcare industry is headed towards an exciting evolution!

Both the technology and potential are more readily available than ever before, and industries will have the ability to drive it to meet their needs. Hearing aids, for instance, were so labor-intensive to produce that once 3D printing became more mainstream, 99% of them were manufactured using the emerging technology in less than 2 years.

- Greater Efficiency without Compromising Quality

A major drawback of 3D printing has been the length of time to complete production. While the amount of time could be decreased, it often meant that the quality of the product would be greatly reduced largely due to the vibrations of the machines. But as equipment becomes more widely available with greater adoption across various industries, innovations in speed are naturally following.

Along with these advancements comes the reduction of waste and overall expense as fewer materials are required, and companies no longer need to develop specialized processes to reduce total time of operation.

- Automation and Collaboration

As efficiency and speed continue to increase, so does the streamlining of processes. While many products are more or less ready to go “hot off the press”, some do require additional assembly and finishing. This is not only labor-intensive, but cost-intensive as well. Software companies are already jumping on the task, though, working with the hardware companies to create robotic assembly to alleviate both concerns. This is all part of the evolution of the industry, creating “new collar” jobs: high-paying, high-tech, and high-reward.

You can also expect to see collaboration between 3D printing companies and their customers, particularly to drive the mass customization of products. You can already see this in businesses such as Nike, Adidas, and Under Armour, who are working to create custom running shoes based on individual foot scans and other customer data. This customized approach leads to better buyer experience, as their individual needs become a priority for both retailer and consumer, similar to the growing use of AR integrations.

Interested in learning more about 3D Printing and the Advanced Manufacturing taking place in the Santa Clarita Valley? Check out Made in SCV to find out how the industry is continuing to evolve right here in our own backyard.

And if you’re ready to take your advanced manufacturing business to the next level, we’ve compiled the top resources for growing here in California. Learn more about:

- 5 Top Challenges in Manufacturing(and how they can become opportunities)

- California Resources and Incentives(to help manufacturing companies succeed)

- 6 Key Factors to Consider when Selecting the Right Location(that suits your short-term and long-term needs)

Download your FREE copy of Strategic Methods to Accelerate Your Manufacturing Business in California TODAY!

The Santa Clarita Valley Economic Development Corporation (SCVEDC) is a unique private / public partnership representing the united effort of regional industry and government leaders. The SCVEDC utilizes an integrated approach to attracting, retaining and expanding a diversity of businesses in the Santa Clarita Valley, especially those in key industry clusters, by offering competitive business services and other resources.

.png?width=1198&name=EDC_cmyk_orange-white%20horizontal.F%20(1).png)